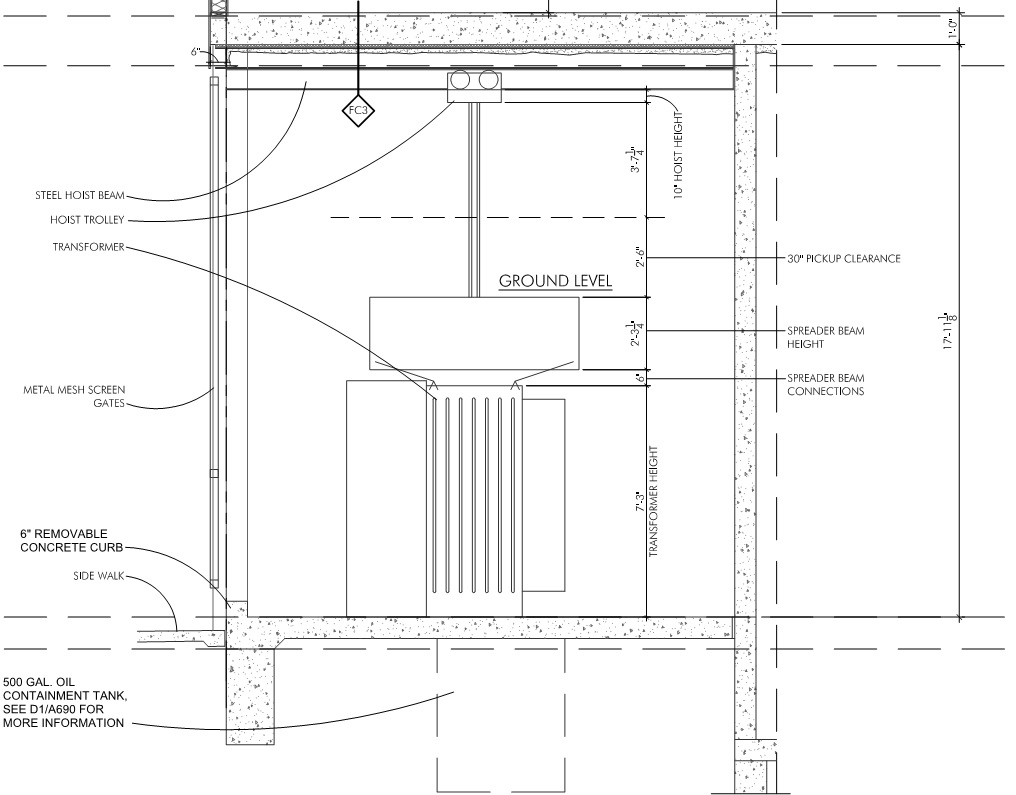

Each test has a particular objective that helps determine a transformer's suitability for use.Ī number of these tests are done on the plant floor, while other tests are conducted usually after delivery is made.

A note of caution: The information presented here is not meant to supersede any manufacturer's instructions.īefore your transformer is scheduled to be shipped to its designated site, it's important that you coordinate with the manufacturer what acceptance tests should be carried out. This material will provide additional general guidelines for installing and testing both dry-type and liquid-filled transformers for placement into service. And its important that you follow current NEC practice and applicable local codes. Regardless of manufacturer, you should carefully follow these instructions to ensure adequate safety to personnel and equipment.

And, each manufacturer will have its own instructions for installing and testing its transformers. When viewing transformer product literature, you'll probably find that one manufacturer's units will have differences from that of a competing manufacturer. The article in this issue covers installation procedures you should consider to help assure your transformer will function properly and safely, and it's focused on installation practices that are common for both dry-type and liquid-filled transformers. An article on how to choose a transformer based on the latter criteria appeared in the May '96 issue of EC&M. The successful operation of a transformer is dependent on proper installation as well as on good design and manufacture.

0 kommentar(er)

0 kommentar(er)